Industry Innovation

Mayker offers innovative solutions for digital manufacturing and industrial innovation, through a service aimed at unburdening the client: from the initial assessment and the right advice to the final implementation. We always focus on the specific needs of each project rather than offering the same solution for every customer. We opt for a straightforward and pragmatic approach with that dynamic energy inherent to West-Flemish entrepreneurs.

Mayker offers innovative solutions for digital manufacturing and industrial innovation, through a service aimed at unburdening the client: from the initial assessment and the right advice to the final implementation. We always focus on the specific needs of each project rather than offering the same solution for every customer. We opt for a straightforward and pragmatic approach with that dynamic energy inherent to West-Flemish entrepreneurs.

Solutions for digital manufacturing: unburdening from A to Z

Over the years we’ve gained broad experience in the manufacturing industry including many successful digitalisation projects. But we don’t want to limit our service to just one technology provider or development environment. Or rather, we don’t want to limit our customers to just one of those options.

The client comes first

Our clients and their individual needs or questions take a central place in our vision. In other words, we don’t use the technological capability of a specific technology or supplier as a starting point. Of course we consider proven off-the-shelf solutions when appropriate, but we also consider customised solutions if and when they fit the needs of the business better.

Our ultimate strength is our knowledge of operational processes in manufacturing, which we’ve acquired over the years. When projects fail, often a wrong interpretation of the needs of a business are to blame. This is where Mayker makes the difference. We combine technical experience with a profound understanding of operating processes to succeed in making the right translation the right way. We do this via our own in-house knowledge, the expertise of our clients and our extensive partner network within and beyond the Cronos group we’re part of.

Our ultimate strength is our knowledge of operational processes in manufacturing, which we’ve acquired over the years

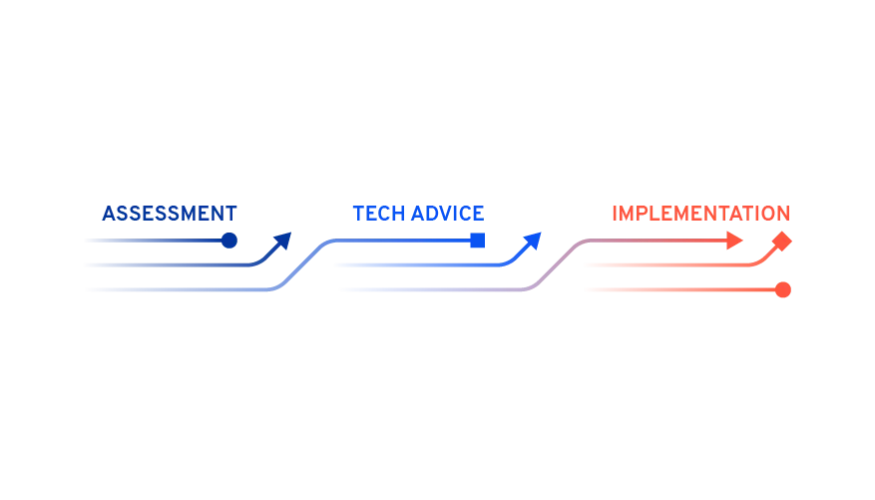

End-to-end solutions in three steps

With our services we primarily want to bridge the gap between business and technology. That’s why instead of offering services based on a predetermined technology, we keep our services unbiased and vendor agnostic.

- Assessment

The first step in the digitalisation project is an in-depth assessment. We collect and analyse data to identify the needs and challenges of the client. We also try to identify specific motives or drivers for choosing digitalisation.

- Advice

Based on the assessment, we provide support and advice on the best technology fit for their specific situation.

- Implementation

Finally we draw up the implementation trajectory that we then carry out step by step to completion.

When projects fail, often a wrong interpretation of the needs of a business are to blame. This is where Mayker makes the difference

It’s a given that manufacturers benefit from extensive digitalisation of their operational processes. In our view, the industry is certainly in need of a catch up. Influenced by the covid-pandemic, this extra effort seems to be gradually taking place. Digitalisation means manufacturers can gain better insights into their delivery times, to give one of many possible examples. By optimising their OEE (overall equipment effectiveness), they can maximise the value of investments in their production process, and last but not least they will see a decrease in pressure on their employees by enabling the transfer of knowledge from their employees’ brains to the production system.

Alongside the urgency to innovate and adapt to the modern market, the returns on digital investment have also increased for manufacturing companies in recent years. Here at Mayker, we like to contribute to that positive development.

Jef Lamerant & Dider Kerckhof